New Horizon Farms, LLP Pipestone, MN

Problem Intensive indoor swine farming operations typically, manage manure through an under floor manure pit which acts like a large anaerobic digester, where microorganisms break down biodegradable material in the absence of oxygen. In the spring and fall the nutrient-rich manure is typically on land applied as an organic fertilizer in the production of crops including corn, soybeans and alfalfa. This process is characterized by many issues including the generation of the potentially harmful gases hydrogen sulfide (H2S), ammonia (NH3) and methane (CH4) that has been known to decrease productivity or cause hog mortality. The accumulation of foam is also a common problem resulting in reduced ventilation and increased potential of fire and barn explosions (methane). Surface crusting provides a favorable environment for flies and rodents that are unsightly, unhealthy and a general source of annoyance for the hogs and farm managers. Additionally, manure pits are also notoriously difficult to completely clean out. Even with the extended use of the largest pit agitators, invariably large mounds of compacted undigested food and manure remain in the pit after pump out, thereby reducing the overall effective volume of the pit. Runoff from manure can also find its way into aquifers that tap ground water sources for human consumption and surface water such as lakes, streams, and ponds where it has been linked to eutrophication.

Solution OdaLock™ in an innovative line of pit amendment technologies developed by North American Geochemical LLC for US Environmental Resource & Recovery Group, LLC to ameliorate all of the above described issues facing swine-manure managers. Typical application rates for OdaLock™ SRT855 and OdaLock™ WP-1 are 55 gallons and 1,000 lbs, respectively, per 500,000 of manure, per pumping cycle. Best results are obtained by applying OdaLock™ with agitation or at all available pump out locations. Barn treatments were conducted In collaboration with Applied Remediation LLC, Sioux Falls, SD.

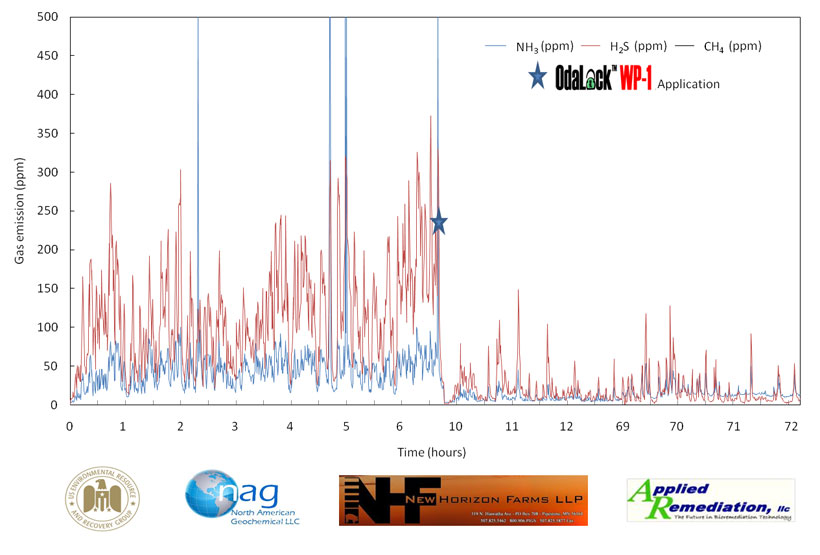

Results Applications of OdaLock™ Technology to New Horizon Farms LLP barns has generally resulted in rapid reductions in both H2S and NH3 gas emissions (> 77% reductions), decreased manure dry matter content (liquefied manure), reduced incidences and magnitude of pit foaming and surface crusting and increases in average manure TN concentrations. OdaLock™ Technology has decreased production cost by reducing the amount of equipment and labor required during manure pump outs. Reduced pit odor emissions further decreased production costs by reducing winter ventilation and barn heating requirements. Better air and water quality = healthy happy livestock, producers and neighbours.

Reductions of gas emission following application of OdaLock™ WP-1 to New Horizon Farms, LLP, Pipestone MN, swine pits.